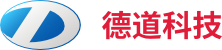

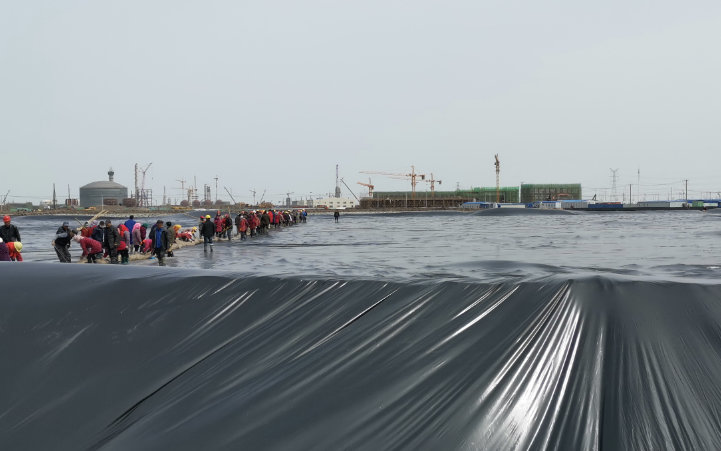

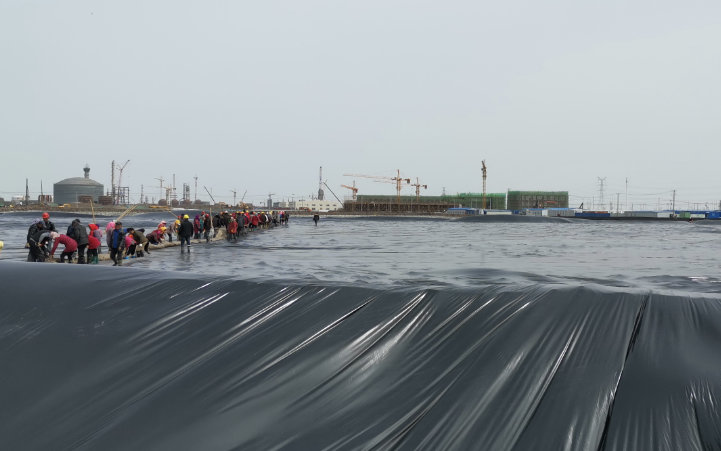

The company's vacuum preloading film produced by blow molding is a new generation of products developed on the bais of the original technology ,and the new generation vacuum preloading film is made of GFZ-7626 polymer materia, produced by unique formula and advanced technology, which not only enhances the tensile strength and toughness, but also reduces the shrinkage rate after the vacuum pre-pressing film is stretched (ie, the resilience rate).The new product has a tighter molecular stucture and a smaller premeability coefficient. The shrinkage of the convention vacuum preloading film is generally 2-3%, and the shrinkage of the improved new-generation vacuum preloading film is only 0.2-0.5%. special anti-aging agent is added to the vacuum preloading film to shield 80-90% of the ultraviolet light in the sunlight, which greatly improves the anti-aging performance of the vacuum film and prolongs the service life. It is a ideal sealing material for vacuum preloading project.